- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

When selecting materials for high-performance applications, it’s crucial to understand their physical properties, such as ductility and brittleness. These properties directly impact the material’s suitability for specific applications, especially when exposed to mechanical stresses, temperature fluctuations, or harsh environments. PEEK (Polyether Ether Ketone), a high-performance thermoplastic polymer, is known for its strength, chemical resistance, and ability to perform under extreme conditions. But one of the important questions that arise is whether PEEK Open-End Automatic Winding Tubing is ductile or brittle.

Understanding the ductility of PEEK tubing is essential for industries that require precision, flexibility, and reliability—such as aerospace, automotive, medical, and electronics. In this article, we’ll explore what PEEK Open-End Automatic Winding Tubing is made of, how it behaves under stress, and whether it is ductile or brittle. Additionally, we’ll discuss why this property is so important in various applications and how Dongguan Zhonghe Electronics Co., Ltd. is at the forefront of providing high-quality, durable PEEK tubing solutions.

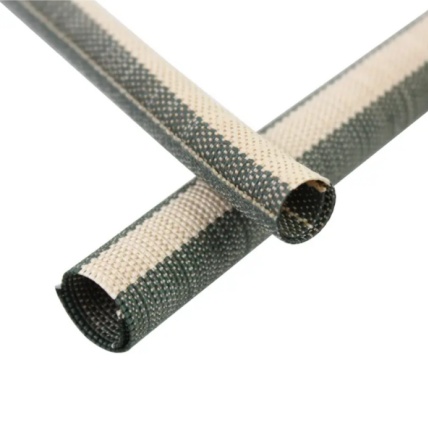

PEEK Open-End Automatic Winding Tubing is a high-performance tubing product made from PEEK, a thermoplastic material known for its outstanding strength and resistance to high temperatures, chemicals, and mechanical wear. This tubing is designed for use in industries that require precise, durable materials to withstand harsh conditions, including aerospace, automotive, medical devices, and industrial equipment.

The "open-end" design of this tubing means that it can be wound automatically during the manufacturing process, making it ideal for high-efficiency production lines. The automatic winding ensures consistent, uniform coils or loops, reducing manual labor and increasing production speed.

Feature | Explanation |

Material | PEEK is a high-performance thermoplastic with excellent thermal stability, chemical resistance, and strength. |

Open-End Design | Allows for efficient, automated winding, reducing labor costs and improving production speed. |

Durability | PEEK tubing is designed to withstand high temperatures (up to 260°C), harsh chemicals, and mechanical stress. |

Ductility/Brittleness | PEEK tubing is known for its ductility—offering flexibility without sacrificing strength, ideal for high-performance use. |

Precision | The material maintains tight tolerances, ensuring high-quality, reliable performance in demanding industries. |

The ductile nature of PEEK Open-End Automatic Winding Tubing provides several significant benefits in industrial applications. Below are some of the key reasons why its ductility is so crucial for performance:

In many industries, especially in aerospace, automotive, and electronics, tubing often needs to be routed through complex pathways, navigating tight spaces, corners, and long distances. Ductility allows PEEK tubing to bend and twist without cracking or breaking. This flexibility makes installation easier and ensures that the tubing can be directed through intricate systems without the need for specialized fittings or additional components.

The ability to route the tubing in such a flexible manner without risking failure due to kinks or cracks ensures that the system operates with minimal disruption. Whether you’re setting up fuel lines in an aircraft or cooling lines in a high-performance engine, PEEK tubing can adapt to various shapes and configurations without compromising its mechanical integrity.

The ductility of PEEK tubing ensures its long-term reliability. As many industrial systems run continuously or experience frequent usage, tubing exposed to repeated stresses or temperature variations needs to remain functional for long periods. PEEK tubing, being able to flex without breaking, reduces the risk of failure, especially in systems that are frequently moved or exposed to changing conditions.

For example, in hydraulic systems where the tubing may experience pressure variations or where components are frequently adjusted, PEEK tubing provides the reliability needed for critical operations. By maintaining its ductility over time, PEEK ensures that the system continues to operate without needing frequent replacements or repairs.

One of the standout features of PEEK’s ductility is its ability to absorb impact. When exposed to shocks or sudden mechanical forces, PEEK tubing can distribute the mechanical forces across its surface without cracking or fracturing. This makes it an ideal material for applications where impact resistance is critical, such as in fuel lines or industrial processing equipment.

Materials that are brittle may crack or break under these circumstances, leading to costly downtime, repairs, or even dangerous system failures. In contrast, the ductility of PEEK tubing ensures that it can handle unexpected impacts and continue to function reliably, minimizing the risk of failure in demanding environments.

Industries such as chemical processing, food processing, and pharmaceuticals often involve harsh working conditions, with high temperatures, chemical exposure, and physical stresses. PEEK tubing is highly resistant to chemicals, UV light, moisture, and extreme temperatures, ensuring it maintains its flexibility and strength in these environments.

The ductile nature of PEEK allows the tubing to maintain its form even in the face of temperature fluctuations, exposure to solvents, or high-pressure systems. This adaptability ensures that the tubing continues to perform reliably, even when subjected to the most challenging industrial conditions.

PEEK Open-End Automatic Winding Tubing is a versatile material that is used across a wide range of industries. Its unique properties—such as ductility, high temperature resistance, chemical resistance, and mechanical strength—make it ideal for applications that require reliable, long-lasting materials. Below are some of the key industries and applications where PEEK Open-End Automatic Winding Tubing excels:

In the aerospace industry, PEEK tubing is crucial for fuel lines, hydraulic systems, and the insulation of wiring. Given the extreme conditions that aerospace components are subjected to, such as high pressures, vibrations, and temperature fluctuations, PEEK tubing's ductility allows it to withstand these stresses without cracking or breaking.

PEEK’s high temperature resistance makes it perfect for mission-critical components in aircraft, where failure is not an option. Whether used for fuel systems that need to resist both high pressures and chemicals, or for electrical insulation in sensitive avionics systems, PEEK tubing offers reliability and durability under harsh aerospace conditions.

In the automotive industry, PEEK tubing plays an important role in engine systems, cooling systems, and fuel systems. The automotive sector demands materials that can withstand high temperatures, pressure, and the constant vibration that components experience during operation. PEEK tubing delivers on all fronts, providing flexibility and durability in even the harshest automotive environments.

PEEK is widely recognized in the medical field for its use in implantable devices, catheters, and surgical instruments. Biocompatibility is a crucial factor in medical applications, and PEEK’s non-toxic nature makes it a top choice for medical tubing and implants. PEEK tubing is used in implantable devices such as spinal implants or orthopedic joints, where it needs to withstand sterilization processes and the mechanical demands of the human body.

In electronics, PEEK tubing is used to insulate wires and cables in high-temperature or high-voltage environments. Electrical systems in devices like servers, computers, medical devices, and automotive electronics require components that can withstand significant electrical stress without compromising safety. PEEK tubing’s high dielectric strength and flexibility allow it to insulate and protect wiring while resisting heat and electrical stresses.

PEEK tubing is a critical material in a variety of industrial settings, including chemical processing, food processing, and water filtration systems. In chemical processing, tubing must withstand exposure to aggressive chemicals and high temperatures, while in food processing, it must meet strict hygiene standards while maintaining strength and flexibility. PEEK tubing offers exceptional resistance to chemicals and mechanical strength, ensuring that it does not degrade over time when exposed to acids, solvents, or extreme environmental conditions.

PEEK Open-End Automatic Winding Tubing is not only ductile, offering the flexibility to bend without cracking, but it is also incredibly durable, resistant to extreme temperatures, and able to withstand mechanical stress. These properties make it an ideal solution for industries such as aerospace, automotive, medical devices, and electronics, where reliable performance and long-term durability are essential.

The ductile nature of PEEK ensures that it can be used in complex systems where flexibility is crucial, and it remains a reliable material for high-performance applications. If you are looking for high-quality, durable, and flexible PEEK tubing solutions, Dongguan Zhonghe Electronics Co., Ltd. provides top-tier products designed to meet the needs of industries requiring precision, flexibility, and performance.

Is PEEK Open-End Automatic Winding Tubing ductile?

Yes, PEEK tubing is ductile, meaning it is flexible and can bend without cracking or breaking under stress.

How does the ductility of PEEK benefit industrial applications?

The ductility of PEEK allows it to be routed through tight spaces, resist mechanical shocks, and maintain flexibility in harsh environments.

What industries use PEEK Open-End Automatic Winding Tubing?

PEEK tubing is widely used in aerospace, automotive, medical devices, electronics, and industrial equipment for its high performance and flexibility.

Can PEEK tubing withstand high temperatures?

Yes, PEEK tubing can withstand temperatures up to 260°C (500°F), making it suitable for extreme temperature environments in various industrial sectors.