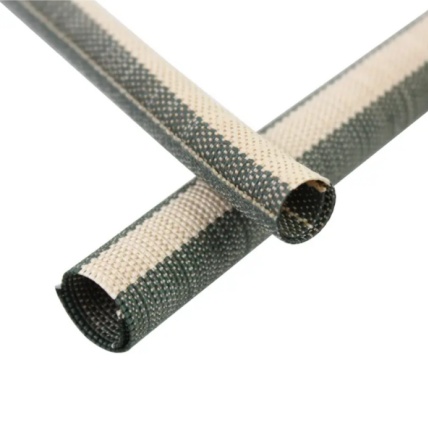

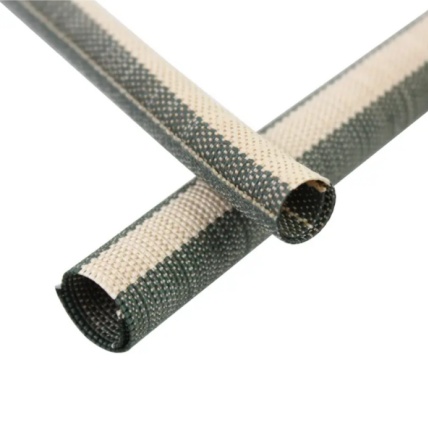

Products Introduce

Plastic Corrugated Pipe is a high-performance wire protection solution, crafted from quality PP, PA, PE, and flame-retardant materials. Boasting exceptional flexibility, crush resistance, and durability, it excels in harsh environments like automotive, industrial, and outdoor settings. With split-type and flame-retardant options, plus various sizes, colors, and UV-resistant variants, it ensures reliable protection against abrasion, chemicals, and weather, keeping cables organized and safe.

Product Center

Product Advantages

Plastic Corrugated Pipe offers durable, weather/chemical-resistant protection with flexible, versatile designs for diverse needs.

Exceptional durability and adaptability

Crafted from high-quality PP, PA, PE, and flame-retardant materials, it resists abrasion, chemicals, and weather (including UV rays), performing reliably in harsh environments like automotive, industrial, and outdoor settings.

Read More

Versatile and user-friendly

With flexible bending for easy installation, split-type designs for hassle-free retrofitting, plus multiple sizes, colors, and flame-retardant options, it meets diverse protection needs while keeping cables organized.

Read More

Technical Specifications

The Technical Specifications of the Plastic Corrugated Pipe cover key details including materials, sizes, colors, special properties, and types, providing comprehensive parameters for its application and performance.

Materials

Crafted from premium-grade PP (Polypropylene), PA (Polyamide), PE (Polyethylene), and flame-retardant compounds. These materials deliver excellent chemical resistance, with PP and PE offering high impact strength, PA providing superior tensile strength, and flame-retardant variants meeting relevant safety standards for fire resistance.

Sizes

Available in a wide range of outer diameters, typically spanning from 3.7±0.3 mm to 91±1 mm (specific values depend on product lineup), with wall thicknesses optimized to balance flexibility and protective performance, ensuring compatibility with various wire gauges and bundle sizes.

Special Properties

UV-resistant for long-term outdoor use, withstanding sunlight and temperatures from -40°C to 125°C. Flexible design with small bend radius (e.g., Φ3.7*5.8 for tight spaces) allows easy routing in curved or confined areas. Strong crush resistance, high tensile strength (≥60 MPa), and excellent impact resistance (no cracks at -40°C) protect internal wires from external damage.

Read More

Contact Us

Application

Read More

OEM Service

Tailored Customization

Our plastic corrugated pipe OEM service adapts to diverse specs—dimensions, materials, colors, branding—for automotive wiring, industrial cable management, outdoor infrastructure, etc.

Quality & Compliance

Advanced production and strict testing ensure adherence to [relevant standards like UL, RoHS, ISO, etc.]. We prioritize durability, protection performance, and consistent safety for wiring systems.

Download

- Name

- Summary

- Category

- Update

- Size

- Downloads

- Thumbnail

- Download

- Copy Link

- Dongguan Zhonghe Electronics Co., Ltd..pdf

- Uncategorized

- 2025-06-06

- 3KB

- 26

-

- Download

- Copy Link

FAQs

- Q: What's your Lead time?A:Regular products will be shipped within 3-7 days, special customized products will be shipped within 7-15 days.

- Q: Can you do the design for us?A:We are a factory manufacturer with a R&D team to support OEM&ODM and provide customers with personalized product customization and solutions.

- Q: What Certificates have you got?A:Our company is verified by ISO9001, ISO14001, CE, RoHS SGS, UL94, EN45545 Test Report, ELV Test, Mold, constant temperature and other tests.

Our Certificate

Our Plastic Corrugated Pipe holds a range of authoritative certifications to guarantee quality and compliance, which serve as strong proof of its reliability in various application scenarios.

Related Blogs

-

PEEK (Polyetheretherketone) Open-End Automatic Winding Tubing is a highly specialized material used in various manufacturing processes. It combines the durability and flexibility of PEEK with the precision of automatic winding technology, offering a unique solution for industries that require strong, flexible, and heat-resistant tubing for their applications. This material is especially valuable in fields such as electronics, aerospace, automotive, and medical device manufacturing, where high-performance materials are necessary to meet stringent demands.Industries

PEEK (Polyetheretherketone) Open-End Automatic Winding Tubing is a highly specialized material used in various manufacturing processes. It combines the durability and flexibility of PEEK with the precision of automatic winding technology, offering a unique solution for industries that require strong, flexible, and heat-resistant tubing for their applications. This material is especially valuable in fields such as electronics, aerospace, automotive, and medical device manufacturing, where high-performance materials are necessary to meet stringent demands.Industries -

In the ever-evolving world of manufacturing, selecting the right materials for production processes is essential for ensuring both efficiency and high performance. PEEK (Polyether Ether Ketone), a high-performance thermoplastic, is one such material that has found widespread use in various industries due to its impressive mechanical, thermal, and chemical properties. One particular form of PEEK, the PEEK open-end automatic winding tubing, has gained popularity due to its durability, resistance to extreme conditions, and remarkable flexibility.Industries

In the ever-evolving world of manufacturing, selecting the right materials for production processes is essential for ensuring both efficiency and high performance. PEEK (Polyether Ether Ketone), a high-performance thermoplastic, is one such material that has found widespread use in various industries due to its impressive mechanical, thermal, and chemical properties. One particular form of PEEK, the PEEK open-end automatic winding tubing, has gained popularity due to its durability, resistance to extreme conditions, and remarkable flexibility.Industries -

When selecting materials for high-performance applications, it’s crucial to understand their physical properties, such as ductility and brittleness. These properties directly impact the material’s suitability for specific applications, especially when exposed to mechanical stresses, temperature fluctuations, or harsh environments. PEEK (Polyether Ether Ketone), a high-performance thermoplastic polymer, is known for its strength, chemical resistance, and ability to perform under extreme conditions. But one of the important questions that arise is whether PEEK Open-End Automatic Winding Tubing is ductile or brittle.Industries

When selecting materials for high-performance applications, it’s crucial to understand their physical properties, such as ductility and brittleness. These properties directly impact the material’s suitability for specific applications, especially when exposed to mechanical stresses, temperature fluctuations, or harsh environments. PEEK (Polyether Ether Ketone), a high-performance thermoplastic polymer, is known for its strength, chemical resistance, and ability to perform under extreme conditions. But one of the important questions that arise is whether PEEK Open-End Automatic Winding Tubing is ductile or brittle.Industries -

In the fast-paced world of industrial applications, the need for advanced materials that can perform under extreme conditions is ever-growing. One such breakthrough technology is PEEK (Polyether Ether Ketone) open-end automatic winding tubing. This innovative solution is rapidly becoming a game-changer in various industries, from aerospace to electronics, due to its exceptional durability, heat resistance, and chemical stability. Let’s dive into what makes PEEK open-end automatic winding tubing so revolutionary and how it is transforming industries globally.Industries

In the fast-paced world of industrial applications, the need for advanced materials that can perform under extreme conditions is ever-growing. One such breakthrough technology is PEEK (Polyether Ether Ketone) open-end automatic winding tubing. This innovative solution is rapidly becoming a game-changer in various industries, from aerospace to electronics, due to its exceptional durability, heat resistance, and chemical stability. Let’s dive into what makes PEEK open-end automatic winding tubing so revolutionary and how it is transforming industries globally.Industries

Keep In Touch With Us

Need info on plastic corrugated pipes, customization, or partnerships? Reach us via online chat (24/7 managers), email (replies in 12h), or call [phone number]. We’re here to help!

Mob:+86-13066183886

E-mail:sales@zhonghe0769.com