- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

In the ever-evolving world of manufacturing, selecting the right materials for production processes is essential for ensuring both efficiency and high performance. PEEK (Polyether Ether Ketone), a high-performance thermoplastic, is one such material that has found widespread use in various industries due to its impressive mechanical, thermal, and chemical properties. One particular form of PEEK, the PEEK open-end automatic winding tubing, has gained popularity due to its durability, resistance to extreme conditions, and remarkable flexibility.

At Dongguan Zhonghe Electronics Co., Ltd., we specialize in providing high-quality PEEK open-end automatic winding tubing designed to meet the needs of diverse manufacturing applications. In this article, we will explore the flexibility of PEEK open-end automatic winding tubing, its features, and how its adaptability makes it an excellent choice for industries such as automotive, electronics, aerospace, and more.

As we delve deeper into the characteristics of PEEK tubing, we’ll also highlight its versatility in various industrial settings and why its flexibility is one of its most valuable attributes. Let's explore how PEEK open-end automatic winding tubing stands out in the competitive world of manufacturing and how it can benefit your operations.

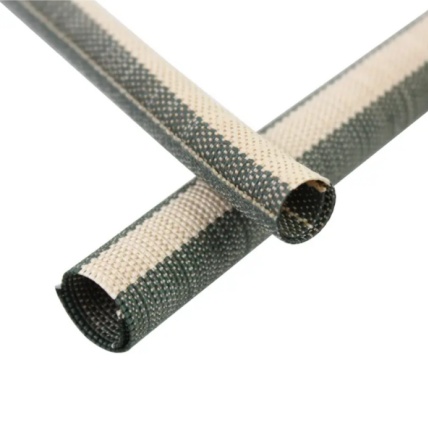

PEEK open-end automatic winding tubing is a specialized type of tubing made from PEEK polymer, designed to be wound automatically into a spiral shape. This tubing is often used for insulating, protecting, and guiding wires and cables in various applications. The "open-end" design allows for easy installation and maintenance, making it ideal for systems that require flexible and durable solutions.

PEEK is renowned for its high mechanical strength, chemical resistance, and thermal stability. These properties make it suitable for extreme environments such as high temperatures and harsh chemicals. PEEK open-end automatic winding tubing leverages these qualities to provide a reliable, durable, and flexible solution for many industries.

One of the most significant benefits of PEEK tubing is its ability to adapt to complex geometries. This flexibility allows the tubing to navigate through tight spaces, around obstacles, and through intricate layouts where rigid materials might not be suitable. In applications such as machinery, electronics, and medical devices, flexibility ensures that the tubing can be installed in environments with limited space and complex configurations without the need for custom, bulky solutions. The flexible winding pattern of PEEK tubing allows for easy adjustments in its path, making it an ideal choice for designs that require a high degree of customization and precision.

In industries like automotive and robotics, many components are constantly in motion. Whether it’s an engine system that undergoes frequent vibration or a robotic arm with continuous movement, PEEK open-end automatic winding tubing can withstand the stress of repeated bending, twisting, and vibrations. Its flexibility ensures that the tubing can protect wires and cables in dynamic environments, preventing damage to the components it surrounds. By offering this protection, PEEK tubing helps maintain the functionality of sensitive electronics and machinery, even in high-stress environments.

In sectors such as electronics and robotics, where systems often experience vibrations, temperature fluctuations, and frequent movement, PEEK tubing provides the resilience needed to maintain optimal performance. Its ability to withstand dynamic movement without losing its strength or flexibility makes it suitable for use in critical applications like flexible circuit boards, robotic arms, and automated systems. The tubing’s superior resilience ensures that it can handle the wear and tear of daily operations without breaking down or compromising the integrity of the components it protects.

PEEK is known for its high tensile strength and impact resistance, which allows PEEK open-end automatic winding tubing to endure extreme conditions without deteriorating. The tubing is ideal for applications that require materials to withstand high stress, abrasion, and harsh environments, making it suitable for aerospace, automotive, and industrial manufacturing.

PEEK is highly resistant to a broad spectrum of chemicals, including acids, bases, and solvents. This resistance ensures that PEEK open-end automatic winding tubing remains intact and functional even when exposed to corrosive substances. This makes it particularly useful in industries such as pharmaceuticals and chemical manufacturing, where exposure to chemicals is a constant concern.

With a high melting point and thermal stability, PEEK can operate effectively in environments that reach extreme temperatures. PEEK open-end automatic winding tubing is capable of withstanding temperatures from -60°C to 250°C, making it ideal for automotive engine compartments, aerospace systems, and electronics that need to perform under high heat without degradation.

The automatic winding process ensures that the PEEK tubing is produced with consistent precision, minimizing defects and ensuring high-quality standards. This automated process leads to faster production times and allows manufacturers to meet the demands of high-volume production with consistent results.

The flexibility of PEEK open-end automatic winding tubing allows it to be customized in various sizes, thicknesses, and lengths, providing a tailored solution for different industries. Whether for cable protection, wire insulation, or fluid management, the ability to adjust the specifications of the tubing makes it a versatile solution for many applications.

PEEK open-end automatic winding tubing is used across a wide range of industries due to its excellent properties. Below are some of the key sectors where PEEK tubing is commonly applied:

In the electronics sector, PEEK tubing is used to protect sensitive wiring and components from external damage. Its flexibility allows it to be used in tight spaces and complex layouts while providing excellent protection from environmental factors.

In the automotive industry, PEEK tubing is often used for cable protection and wiring insulation in high-temperature areas like engine compartments. The tubing’s ability to withstand high temperatures and mechanical stress makes it essential for automotive electrical systems.

In aerospace, PEEK tubing is used to protect critical components in aircrafts, ensuring that wires, cables, and sensors remain intact and functional under extreme conditions. Its flexibility and thermal stability make it ideal for aerospace applications, where high performance and reliability are essential.

PEEK open-end tubing is commonly used in robotics and automation systems to protect wiring and other components. The tubing’s flexibility ensures that it can handle the movements of robotic arms and other machinery without compromising the integrity of the system.

Industry | Application | Benefits |

Electronics Industry | Protects wiring and components from external damage. | Flexibility for tight spaces and complex layouts, protection from environmental factors. |

Automotive Industry | Cable protection and wiring insulation in high-temperature areas like engine compartments. | High temperature resistance and mechanical stress tolerance, essential for automotive systems. |

Aerospace Industry | Protects critical components in aircraft, ensuring wires, cables, and sensors remain functional. | Thermal stability and flexibility under extreme conditions, ideal for aerospace applications. |

Robotics & Automation | Protects wiring and components in robotic and automation systems. | Flexibility for movement, ensuring no compromise in the integrity of robotic systems and machinery. |

The use of PEEK open-end automatic winding tubing helps improve manufacturing efficiency in multiple ways:

The automatic winding process used to create PEEK tubing reduces production time and minimizes the potential for human error. This means manufacturers can produce more high-quality tubing in less time, increasing overall output.

The durability and chemical resistance of PEEK open-end tubing reduce the frequency of repairs or replacements, making it a cost-effective solution over the long term. Its long lifespan minimizes downtime, helping manufacturers maintain steady production schedules.

The flexibility of PEEK tubing allows manufacturers to adapt it for use in various systems and applications. This adaptability makes it easier to design more efficient systems, reducing the need for custom solutions and simplifying the manufacturing process.

PEEK open-end automatic winding tubing is a highly versatile, durable, and flexible material that offers exceptional protection for a wide range of industrial applications. Its flexibility, combined with its chemical resistance, thermal stability, and mechanical strength, makes it an ideal choice for industries such as electronics, automotive, aerospace, and robotics. By incorporating PEEK tubing into manufacturing systems, companies can enhance efficiency, reduce downtime, and improve overall product quality.

At Dongguan Zhonghe Electronics Co., Ltd., we offer high-quality PEEK open-end automatic winding tubing tailored to meet your specific requirements. Whether you’re looking for flexibility, durability, or precision, our solutions are designed to provide exceptional performance in the most demanding environments. Contact us today to learn more about how PEEK open-end automatic winding tubing can optimize your manufacturing processes.

PEEK tubing is commonly used in electronics, automotive, aerospace, and robotics, where its flexibility and durability are essential for protecting wiring and components.

The flexibility of PEEK tubing allows it to navigate tight spaces, conform to complex shapes, and withstand movement, making it perfect for dynamic systems and environments with limited space.

Yes, PEEK open-end automatic winding tubing can withstand temperatures ranging from -60°C to 250°C, making it ideal for high-temperature environments such as automotive and aerospace applications.

Yes, PEEK open-end tubing can be customized in terms of length, diameter, and wall thickness to suit specific requirements, making it versatile for various applications.