- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-12-15 Origin: Site

In industries where the environment places high demands on materials, the ability of components to withstand extreme temperatures, mechanical stress, and exposure to aggressive chemicals becomes vital. Whether you’re involved in aerospace, oil and gas exploration, or marine applications, the performance of your materials can make or break your system. For engineers, buyers, and integrators, finding the right materials to ensure reliability and longevity is crucial. One such material that has proven its worth in these environments is the PEEK Open Self-winding Tube.

At Dongguan Zhonghe Electronics Co., Ltd., we specialize in providing high-quality PEEK Open Self-winding Tubes and other polymer modified protective materials. Our products are designed to meet the needs of industries where durability and performance under harsh conditions are essential. In this article, we will explore the features and benefits of this unique tubing solution, highlighting why it is the perfect choice for extreme environments.

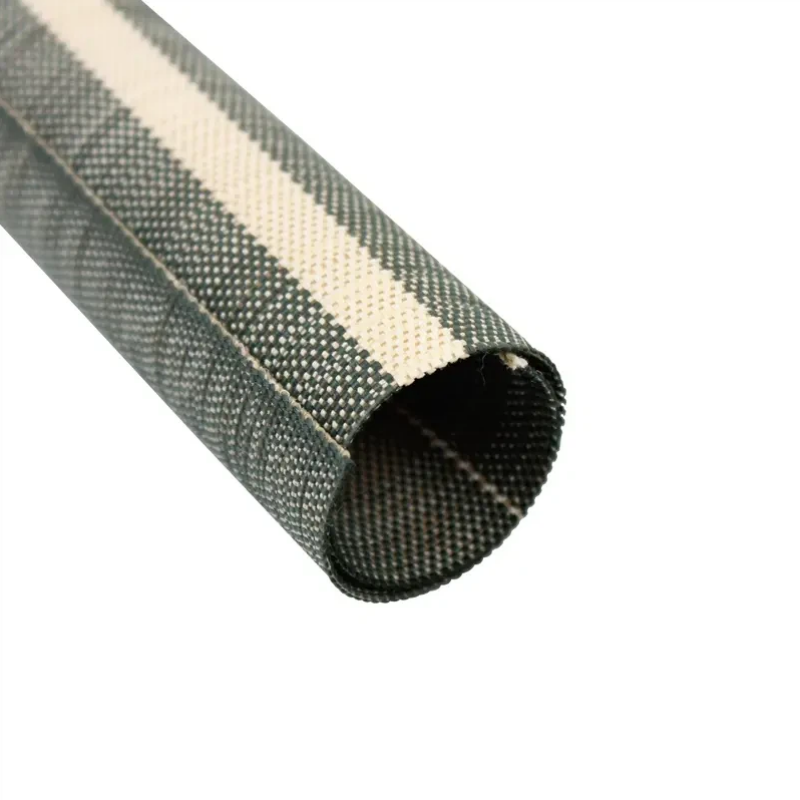

PEEK, or Polyetheretherketone, is a high-performance thermoplastic polymer known for its exceptional mechanical strength, chemical resistance, and ability to withstand high temperatures. It is widely used in industries such as aerospace, automotive, and electronics, where materials are required to perform under extreme conditions. The PEEK Open Self-winding Tube takes advantage of these exceptional properties to offer a protective solution that excels in demanding environments.

The unique self-winding design of the tube offers several advantages. Unlike rigid tubing that requires additional fasteners and tools during installation, the self-winding design of the PEEK tube allows it to easily wrap around and secure the cables or wires it is meant to protect. This feature makes it incredibly easy to install and remove, providing both flexibility and reliability in applications that require frequent reconfiguration.

When compared to traditional tubing materials, PEEK stands out for its superior resistance to high temperatures, chemicals, and mechanical wear. Materials such as PTFE and PVC may offer some protection, but they cannot match PEEK’s high thermal stability and long-term performance in challenging environments.

The PEEK Open Self-winding Tube is engineered to excel in several key areas, making it ideal for a variety of applications where performance is paramount:

PEEK can withstand temperatures as low as -50°C and as high as 260°C, making it suitable for environments that experience extreme heat or cold. Whether it’s in engine bays, on aircraft exteriors, or in cryogenic systems, the tube retains its strength and durability even in the most extreme conditions.

The flexibility of the PEEK Open Self-winding Tube makes it perfect for applications where bending is necessary. Unlike rigid tubes, which can crack or break under repeated flexing, the self-winding tube offers excellent resistance to fatigue and bending, making it ideal for use in robotics, industrial machinery, and other applications that involve continuous movement.

One of the standout features of PEEK is its resistance to a wide range of chemicals, including oils, acids, and solvents. This makes the PEEK Open Self-winding Tube perfect for use in industries such as oil and gas, where components are exposed to corrosive substances and harsh chemicals on a daily basis. Its chemical resistance ensures that the tube will remain intact and continue to perform its protective role over the long term.

PEEK is naturally flame-retardant, meaning that it does not catch fire easily and will not release toxic fumes when exposed to high heat or flame. This property is critical in industries like aerospace and automotive, where fire safety is a top priority. The PEEK Open Self-winding Tube is designed to meet strict fire resistance standards, ensuring that it provides both safety and reliability in high-risk environments.

The design of the PEEK Open Self-winding Tube is one of its key strengths. Its self-winding capability ensures that the tubing is both secure and easy to install. This design eliminates the need for external fasteners, which are often time-consuming and can lead to potential failures if not properly secured.

Moreover, the self-winding feature allows the tubing to be easily adjusted or reconfigured in the field. This is particularly valuable in industries where systems must adapt to changing conditions or configurations. Whether it’s for temporary setups or long-term installations, the self-winding design ensures that the PEEK Open Self-winding Tube remains flexible, durable, and easy to manage.

The scraping/adhesion technology employed in the tube's construction further enhances its reliability. This technology ensures that the tube securely adheres to the cables it is protecting, preventing slippage or detachment even under vibration or movement. This feature is particularly useful in environments where equipment experiences frequent motion or stress, ensuring that the tubing remains in place and continues to perform effectively.

The versatility of the PEEK Open Self-winding Tube makes it suitable for a wide range of industries, each with its own unique challenges. Here are some of the most common applications:

Oil & Gas Exploration: The tubing can be used to protect cables and hoses from exposure to harsh chemicals, high temperatures, and physical stress in offshore drilling rigs and other remote locations.

Aerospace and Special Vehicles: In aerospace applications, the PEEK Open Self-winding Tube provides critical protection for wires and cables that are exposed to high heat, vibration, and pressure.

Marine and Shipboard Environments: The tubing’s resistance to saltwater corrosion and its flexibility make it an ideal solution for ships and offshore platforms, where environmental conditions are demanding and the reliability of electrical systems is crucial.

Field Maintenance and Rapid Serviceability: The self-winding design makes it easy to install, remove, and replace the tubing in the field, which is vital for industries that require quick and efficient maintenance of equipment in the field.

In industries where failure is not an option, it is essential to ensure that the materials used meet the highest quality standards. The PEEK Open Self-winding Tube complies with stringent fire safety standards, chemical resistance certifications, and environmental regulations, ensuring that it performs reliably even in the most extreme conditions.

By adhering to these quality standards, Dongguan Zhonghe Electronics Co., Ltd. ensures that its PEEK Open Self-winding Tubes meet the requirements of OEMs and industries that demand the highest level of performance. This commitment to quality gives customers confidence that the tubing will deliver long-term reliability and safety.

The PEEK Open Self-winding Tube is a powerful and reliable solution for protecting cables and wires in extreme environments. Its high-performance features, including excellent temperature resistance, chemical resistance, and flexibility, make it the ideal choice for industries such as aerospace, oil and gas, and marine applications. The unique self-winding design enhances its usability by offering rapid deployment and secure installation without the need for additional fasteners.

Dongguan Zhonghe Electronics Co., Ltd. takes pride in manufacturing high-quality PEEK Open Self-winding Tubes, along with a range of other protective materials, such as the Braided Cable Sleeve. If you’re looking for a reliable, durable solution to protect your critical systems, contact us today for samples and specifications.

1. What are the main advantages of using the PEEK Open Self-winding Tube?

The main advantages include its high-temperature resistance, flexibility, chemical durability, and ease of installation due to the self-winding design.

2. Can the PEEK Open Self-winding Tube be used in underwater applications?

Yes, the PEEK Open Self-winding Tube is highly resistant to saltwater corrosion, making it suitable for marine environments.

3. How does the self-winding design improve installation efficiency?

The self-winding design eliminates the need for external fasteners and tools, making installation faster and more efficient while maintaining a secure protective layer for cables.

4. What industries typically use the PEEK Open Self-winding Tube?

This tubing is used in aerospace, oil and gas, marine, automotive, and other industries where components are exposed to extreme conditions and require robust protection.